Sustainability - Environmental - Greenhouse Gas Emissions - www.ussteel.com

Environment

Greenhouse

Gas Emissions

Reducing our greenhouse gas emissions is key to becoming a sustainable steel producer.

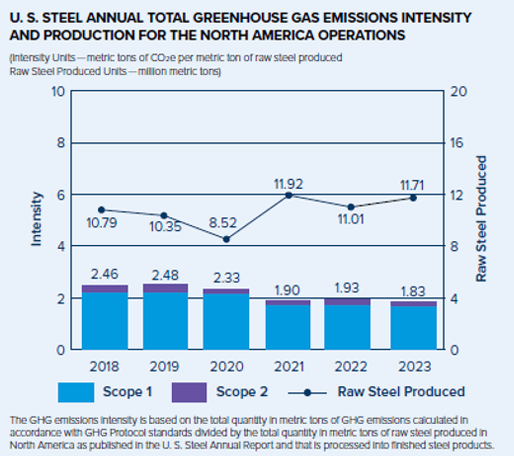

Producing steel is carbon-intensive and we have a roadmap to get to net-zero Scope 1 and Scope 2 emissions by 2050. Approximately 70–80% of the GHG emissions from integrated steelmaking are associated with the use of coke and coal to melt iron in blast furnaces.

U. S. Steel has always strived to be on the leading edge of the most energy-efficient production of steel using blast furnaces. Simultaneously, we are making steel by melting recycled steel scrap using electricity in EAFs, which produces significantly less GHG emissions. U. S. Steel recognizes the importance of having both routes of steel production while transitioning to a lower carbon economy.

Our progress toward lowering our Scope 2 emissions will continue through 2024 with important milestones. For example, U. S. Steel’s second mini mill, BR2, is expected to start up in 2024, which will likely reduce our GHG emissions intensity. Entergy Arkansas’ Driver Solar project, which is located adjacent to the Big River Steel Works operations, will begin providing Big River Steel Works with up to 250 MW of solar power later this year, significantly increasing Big River Steel Works' use of renewable energy

Along with strategic projects and partnerships across all our facilities, we continue to advance towards our GHG emissions reduction goals. We are committed to annual public reporting on progress against our GHG emissions reduction goals, as well as the measures being implemented to achieve them.

As we move full speed ahead toward reaching this target, we are focusing on process optimization as well as on the incorporation of EAFs into our footprint. Our greenhouse gas emission target reflects our continued commitment to improvement in production efficiency and the manufacture of products that are environmentally friendly.

GreenHouse Gas Emissions

2030 Goal

-20%

We have set a goal to reduce our

GHG emissions intensity by 20% by

2030 based on 2018 baseline

levels.

GreenHouse Gas Emissions

2050 Goal

NET-ZERO

We have set an ambitious goal

targeting net-zero carbon emissions

by 2050.

2023 TOTAL GREENHOUSE GAS EMISSIONS

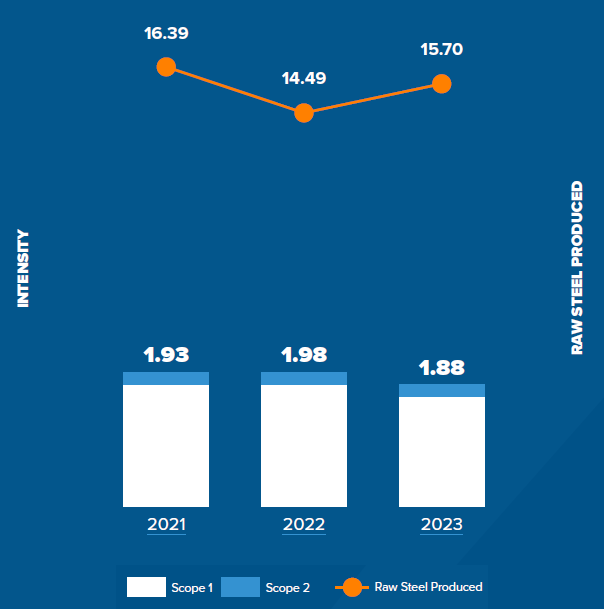

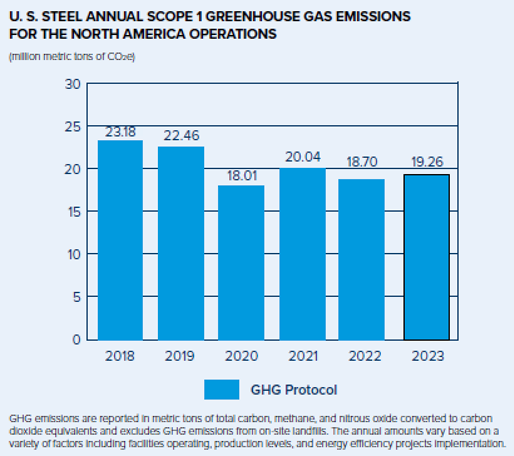

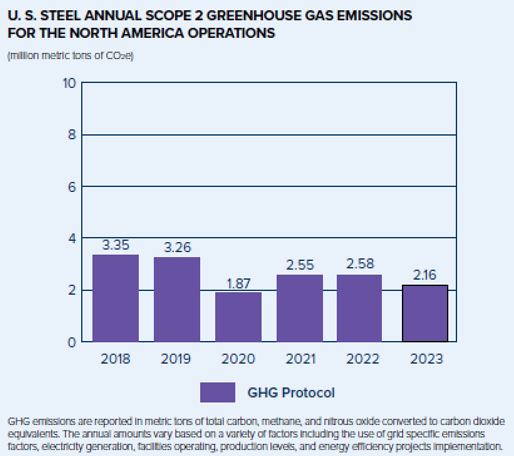

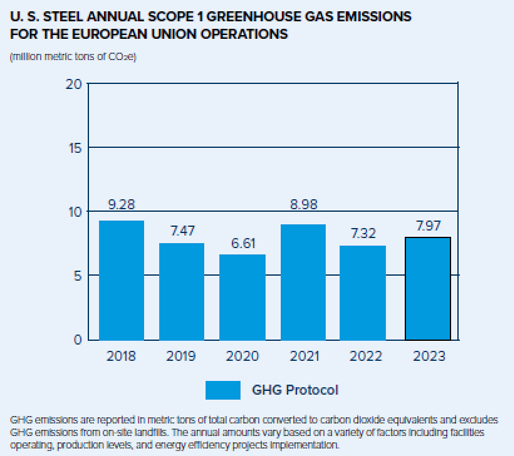

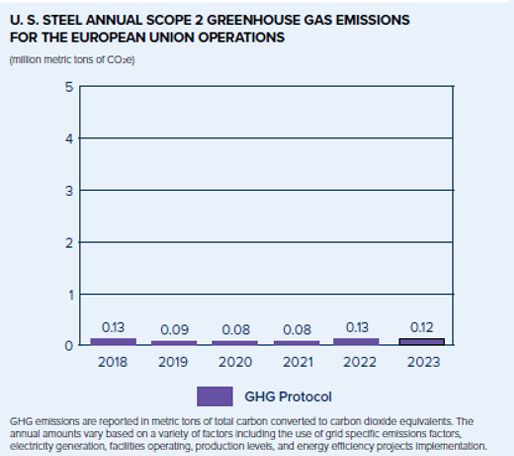

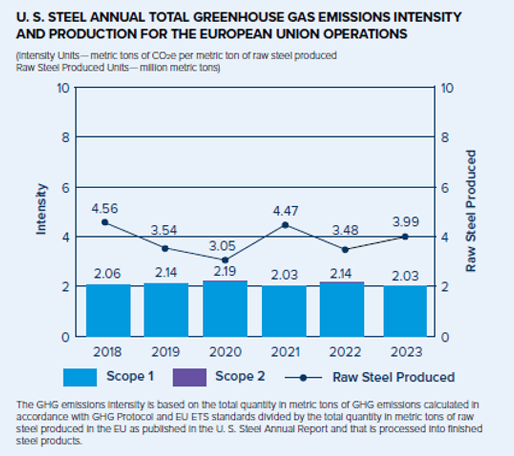

The graphs above show the absolute and intensity based GHG emissions for U. S. Steel wholly owned facilities for 2021-2023. The results are separated by Scope 1, Scope 2, and total GHG emissions for North America, Europe and Total Global Operations. Absolute measurements are presented as metric tons of CO2e, while intensity measurements are metric tons of CO2e per metric ton of raw steel produced.

Spotlight: GHG Emissions Reduction Projects

Fairfield Tubular Operations

Shipment of products from

trucking to rail

We prioritized the shipment of products via rail as opposed to truck at our Fairfield Tubular Operations in 2022. According to the Association of American Railroads, moving freight by rail instead of truck reduces GHG emissions by up to 75%.10 Collaboration with core U. S. Steel distribution partners was key to improving supply chain visibility from production through finished inventory, and to coordinating efficient unloading of railcars at destinations. We are still maximizing on these benefits in 2023.

Gary Works

Reducing natural gas usage

The Gary Works facility undertook several projects to reduce purchased natural gas used as boiler fuel by increasing the utilization of the blast furnace gas by-product back into the system. One of these projects, tracked and monitored by our metriX platform, improved the reliability of the gas main that supplies blast furnace gas to all the boilers. The usage of blast furnace gas was maximized and resulted in reduced natural gas purchase and saved $7.6M in 2023. Over the span of four years, 699,807 MMBtu of natural gas has been offset.

2023 GREENHOUSE GAS EMISSIONS SUMMARY

Environmental Areas of Focus

U. S. Steel’s current environmental areas of focus align with the results of our ESG Materiality Assessment.