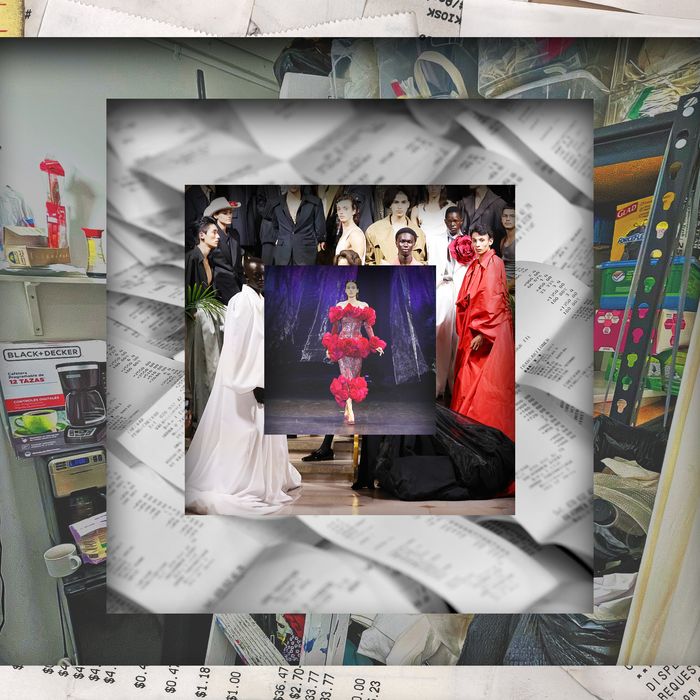

From a distance, it might seem relatively simple to start a fashion brand today. You might think that all a designer needs — aside from an artistic vision — is an Instagram and a Shopify account. Perhaps a friend of a friend can get their dress in front of Julia Fox’s stylist; she could wear it to a Fashion Week party or a dinner at Lucien, and the designer’s career is set. But in reality, the path to finding and sustaining commercial success has grown increasingly hairy. One reason is the influx of new brands, all competing for customers and exposure. Then, of course, there’s the steady breakdown of American retail. Twenty years ago, an up-and-coming designer could catch the eye of a specialty boutique like Linda Dresner or a department store like Barneys that would serve as a reliable vendor and introduce that designer to the masses. Today, many of those boutiques have disappeared, and the few department stores that remain are increasingly dependent on conglomerates like LVMH, Kering, and Richemont. Fashion has always been a tough business, but the rising cost of everything — fabric, labor, shipping, real estate, advertising — has made the economics of running an upstart brand even more unforgiving. Nearly a dozen independent New York designers reveal what’s currently draining their wallets, what’s cutting into their margins, and how they’re making payroll.

1.

Assembling the First Chunk of Cash

How three designers financed their launches.

Designer: Kim Shui of Kim Shui

Founded: 2016

What She Started With: $5,000

Where She Got It: “I had multiple freelance jobs, and I was Airbnb-ing my room for money. It was tiny, but I had these screen dividers and I would stay behind them, then the other room would be rented out.”

How She Spent It: “Creating a capsule collection. I started with probably eight looks. VFiles had an internet platform where you would upload your work and then they might pick you to show at Fashion Week. I uploaded my collection maybe three times. And then, on the third, I got a DM that said, ‘Hey, you’re shortlisted for potentially showing at Fashion Week.’”

Spring Fashion Issue

Designer: Jackson Wiederhoeft of Wiederhoeft

Founded: 2019

What He Started With: $25,000

Where He Got It: “I borrowed some cash from my mom and my grandparents, but I also sold all my Thom Browne uniforms that I’d been wearing for the past three years while working there. I sold 39 pieces on TheRealReal and became a VIP seller for a minute. They still call me all the time; they’re like, Surely this bitch has more.”

How He Spent It: “A PR consultant for press and outreach, but mostly it went toward making 40 pieces of clothing. I had been saving fabric scraps through the years, and friends would come to my apartment and help sew. I was like, ‘I can’t pay you, but you can sew rosettes and bows and I’ll buy you lunch.’”

Designer: Marcelo Gaia of Mirror Palais

Founded: 2019

What He Started With: $10,000

Where He Got It: “I had another business before I started Mirror Palais, and all the money from that brand I invested into this new one.”

How He Spent It: “Getting the samples done and some of the grading and the marking. And there are these little things that sneak up on you, like dues to form an LLC.”

2.

Most of That Cash Will Go Toward Patterns

When inflation hits sample-making.

For a not-yet-established designer, it’s always been a scramble to put together a new collection. There are many different hands involved — a patternmaker to turn a sketch into a pattern, a sewer to make the muslin prototype, a factory or sewer to produce the samples — and it’s practically a rite of passage for a designer to spend the month before a Fashion Week running around the Garment District to get everything made. But as the cost of labor has risen, every step has gotten pricier. For each collection, Jackson Wiederhoeft develops 15 to 20 new styles, ten of which require paying a patternmaker $1,000 to $4,000, depending on how complicated the pattern is. He then hires a fit model to check the drape of the clothes: $250 an hour plus a 20 percent agency fee. So to develop a jacket design, “the finished price of the pattern will be $1,500 to $2,000 plus $300 for the model. Then $700 for the factory to make two mock-ups. That’s like $2,600, and you haven’t even gotten to the cost of actually making the samples.” When making the samples, a designer today has to contend with the cost of raw materials, which spiked during the pandemic and has been rising every season. A new designer is often producing a lower volume of clothes, which means they have less power in negotiating price and have to stretch to meet a fabric supplier’s or factory’s minimum-order quantity. “Once, we ran into a situation where the minimum-order quantity for one of our fabrics was 10,000 meters, which is enormous for a small brand and would have cost $500,000,” says Vanessa Barboni Hallik, who founded Another Tomorrow in 2018. (If you can’t meet minimums, there’s often a surcharge.) “It takes so much to make a sample in New York,” Kim Shui says. “And if you’re doing less than 1,000 units, it’s going to be so expensive.”

3.

So It’s Best to Forgo a Studio

With rent for a Garment District studio as high as $7,000 a month, some designers opt to just work where they live.

Designer: Sintra Martins of Saint Sintra

Launched in 2020

“My first design studio was $800 a month. I couldn’t afford a private residence too, so I moved into my studio. It was a storage unit in a commercial building in Brooklyn. No kitchen or bathroom. I had a mini-fridge, a slop sink in the hall, and a single-burner electric hot plate. I won’t go into details about bathing; it would delight my enemies.”

Designer: Sheena Sood of abacaxi

Launched in 2013

“Until November, the second bedroom of my apartment was my office studio. It quickly grew into the entire house, and my living room became my showroom. People would come by, and it was actually pretty convenient during the pandemic.”

Designer: Tara Babylon of Tara Babylon

Launched in 2019

“My kitchen and living room is where my interns and I will eat and where models wait when we have castings. I have looms for my textiles, and my interns will be weaving on the kitchen table or the sofa. I’ve got four collections in an apartment in Harlem. You get creative with storage. My dishwasher is broken, so I put some things in there.”

4.

A Nordstrom Order Isn’t What It Used to Be

But the alternative isn’t perfect, either.

Selling Wholesale

Ten years ago, Barneys could have easily placed a $300,000 order on a new designer’s collection. Today, even when a department store is willing to gamble on an up-and-comer, the orders have shrunk. In 2022, Sintra Martins sold a collection to Nordstrom that was “wide but shallow”: a lot of different styles and only a few units of each. “For small brands, that is extremely expensive because every style needs to be developed — the pattern, the fitting, the pattern grading, all of which is notoriously the costliest part,” Martins says. The situation isn’t much better at online retailers like Net-a-Porter or SSENSE, which are watchful of sell rates and are also placing modest orders. Especially after the pandemic, retailers are less likely to offer advance deposits, leaving the designer to scrounge to cover the fabric and vendors. Another designer found that, after paying for shipping and vendors, the payment they received from the department store didn’t quite cover production costs. Recent tech innovations have brought new costs that eat into margins, too. Take, for example, the introduction of universal product codes, which many retailers now require to track inventory. When he started wholesale, Willy Chavarria paid “$6,000 for the UPC number and then another $3,000 if you want to print them

out so that you can stick it on the bag,” he says. “And there are all these different software platforms that you have to pay for: one that links to your distribution center, another that links your showroom to the distribution center, then another one your showroom uses. Every day there’s a new surprise: ‘Oh, this isn’t going to work unless you pay for this.’”

Selling Direct-to-Consumer

Selling direct can mean better margins, but it isn’t a silver bullet. The reliance on Instagram for generating buzz (and customers) has left designers more vulnerable to the app’s whims. And the sheer mass of digital businesses, all competing for eyeballs, has sent online-advertising costs through the roof (now, if a designer doesn’t spend a lot of money on it, their brand is less likely to hit the top of the algorithm). And selling direct can just be harder to scale. After focusing only on DTC, Willy Chavarria began selling wholesale last year: “This is my sustenance and paycheck for when I’m older and can’t take care of myself.”

5.

And Fashion Week Is a Money-Hemorrhaging Event

It’s always been pricey, but the financial support has diminished.

A decade ago, it was possible to get a $300,000 Fashion Week show completely sponsored. “You could get hair or makeup companies to sponsor your show, but those checks have gotten smaller each season,” says Gregory Werbowsky, a publicist who’s worked with emerging designers for more than ten years. “Now, there’s no more budget.” To offset the rising cost of rent, models, and union labor, Marcelo Gaia has sold tickets to a show (a historically unorthodox move), while some designers have taken a more DIY route (“Once, I bought curtain rods off Amazon, but halfway through the show they fell down and the entire backstage was exposed,” Kim Shui says). Here, what one designer recently spent.

.

A September 2023 Fashion Week Show

Designer: Willy Chavarria

Samples: $60,000 “The samples are very, very expensive — that was about 20 percent of it.”

Lighting: $60,000 “The lighting was going to be $30,000, up until the night before the show. Then there was an issue: They were like, ‘It’s going to be more lights.’ Then the lighting team was MIA, so we had to get a new team last minute and pay double. Even if your lighting is covered, anytime you adjust a lightbulb, you pay, I dunno, $500.”

+ All the Other Stuff: “You pay for the seats, you pay for the security, you pay for the insurance, the venue, permits, models, catering, sometimes flights. A lot of people’s transportation and Ubers. Depending on the model, sometimes we may have to pay for a hotel.”

Total: $300,000

6.

Maybe a Celebrity Will Take Notice

Not that it’s always a good thing.

The Designer Who Couldn’t Afford a Celebrity Placement

“When you see celebrities wearing clothes from brands, the celebrities don’t pay for it. The brands do. Fendi can afford to send $10,000 worth of merchandise to a client like Gigi Hadid for free because the ROI on that is insane. They’re able to send out thousands and thousands’ worth of merchandise because one of them could pay for all the others. It’s a game of volume. At the time, I did not have the capital. I couldn’t afford to send out hundreds of thousands of dollars of clothes. I remember I once got really close to having Dua Lipa try on one of my outfits, but I just saw that opportunity evaporate.” — Sintra Martins

The Designer Who Wasn’t Ready for Commerce

“Within 24 hours of my first Parsons show, I’m having this viral moment on my Instagram. It was a wave that came out of nowhere. I wasn’t ready, but what do I do? I was exhausted by that point. I was about to move back to the U.K., but then Doja Cat’s stylist DMs me. Then Doja Cat wore my coat and credited me on MTV, and I thought, Come on, you’ve got to keep going.

“Oh my God, that coat. I made it by hand and it took me three weeks, and I think I got arthritis. People were DM-ing me for it, but when I would respond with the cost, they thought it was too expensive. I ended up selling one to a client in Texas through Instagram, but it’s not like I had stores lined up. I spoke to a couple of buyers, and they’d say, ‘This coat is not wearable; it’s too heavy. These are safety pins. That’s a hazard.’” — Tara Babylon

7.

And Then It’s About Keeping the Lights On

Independent designers have always turned to side gigs or brand deals. Now, they rely on them even more.

“I’m compromising my lifestyle to fulfill fabric costs.”

“I’m not making as much from the company as I’m putting in. I’m selling here and there, and customs and one-off orders help, but that’s not consistent. I have a small channel of income from the U.K., and family support, but it comes down to managing how much I spend on materials per month. So if I’m going to be making a jacket and a couple of tops, I just budget, which means compromising my lifestyle to fulfill fabric costs. I’m watching my friends go to dinner, and I’m like, ‘I can’t afford to spend a hundred dollars on that meal and then $50 on some cocktails and get the Uber home.’ I have to stay put because that’s $200 that I need to import from Germany. Talk about FOMO, but it’s survival at this point. “I got sponsored by a company for a show that came with a small amount of funding, and last January, I got approached by KitchenAid: They picked five emerging designers in New York to do a project for the launch of their new kitchen blender. It isn’t a financial possibility to pay myself: Right now, I come second. It’s worth it, and I make that choice too — I’m delulu in that one day I believe that this will pay off and I have to pay the price.” — Tara Babylon

“I’m searching for investors.”

“I’ve almost always had other jobs outside of my fashion label to pay my employees. Up until 2019, that work funded the brand’s growth. Even though I won the CFDA Award, we’re still in a growth period, and we don’t have big investors. But we get into moments where we have to come up with a lot of money — when we have to shell out $300,000 for a show, maybe at the same time that we’re spending $300,000 for production. The business does get to a point where you need a large amount of money to drive it to the next level. Our growth is good, but to meet demand, we have to have large influxes of money. I am currently searching for investors, and I’m talking to some people now.” — Willy Chavarria

“You’re doing anything you can to stay afloat.”

“I’ve been doing consulting work all along for other brands, and until recently that made up more of my income. I did a lot of designing for private labels, consulting for other designers, styling and commercial gigs. One goal is to build up collaborations and sponsorships. You do these things and the fee gets bigger and bigger, and hopefully you get into the six-figure fees, but it feels incremental to get there. We have calls all the time, but the brand is going to go with whoever they want to go with. You want to get to the low-lift ones where you make a lot of money. Last week, we lost this really big job that was supposed to be our income for the next two quarters. Your eyes are sore from crying. You’re doing anything you can to stay afloat.” — Anonymous

More From the spring 2024 fashion issue

- Bring Back These ’00s Trends

- Packing for Paris With Alex Consani

- Where New York City Tweens Actually Like to Shop