Natural dyes are a wonderful way to learn about the hidden colors in nature. We obtain yellow and purple from exotic dye woods, red from the cochineal bug and brown from a sweet-smelling resin. Follow the easy instructions below for best results and enjoy the color journey!

Fiber Preparation and Mordanting

Your fiber should be scoured and mordanted prior to dyeing. Visit our How To pages for information on scouring and mordanting instructions for wool, alpaca, silk (protein), cotton and plant (cellulose) fibers.

Dyeing your Fibers

Calculating the amount of dye that you need can be done by first weighing the material that you want to dye. The material must be dry when you weigh it. This measurement is known as the weight of fiber or WOF. The amount of dye that you need is then calculated as a percentage of the WOF.

For example, an average large cotton t-shirt weighs approximately 150g. To dye it a medium brown shade with cutch, you could use 10% of the weight of the shirt (15g) of cutch. To dye it a medium brown shade with walnut hull powder, you could use 25% of the weight of the shirt (37.5g) of walnut hull powder. The following table shows general guidelines for how much of each extract you should use for various shades.

| Dye | Color | Light | Medium | Dark | Notes |

|---|---|---|---|---|---|

| Chestnut | Yellow | 1-3% WOF | 4-10% WOF | – | Combine with iron to create dark gray shades. |

| Chlorophyllin | Green | 1-2% WOF | 3-4% WOF | 5-10% WOF | |

| Cochineal textile grade extract | Red | 0.25% WOF | 0.5 – 1.5% WOF | 3-4% WOF | |

| Cutch | Reddish brown | 2-6% WOF | 7-14% WOF | 15-20% WOF | For deepest shades, mix cutch with water and let it sit overnight. Simmer your goods for 2 hours. Adding soda ash at 1% WOF will redden and deepen the color. |

| Fustic | Yellow | 1-2% WOF | 3-4% WOF | 5-10% WOF | |

| Himalayan Rhubarb | Yellow | 1-2% WOF | 3-6% WOF | 7-10% WOF | Stir well to dissolve this powder fully. |

| Indigo | Blue | 0.5-1.5% WOF | 2-3% WOF | 4-6% WOF | Indigo uses a different process than other dyes. Use these percentages to create a vat. See vat dyeing instructions here. |

| Kamala | Yellow | 1% WOF | 5% WOF | 10% WOF | Works best with protein fibers such as wool and silk. |

| Lac | Red | 1-3% WOF | 4-6% WOF | 7-10% WOF | Use 3% WOF citric acid and dissolve this in water with the lac extract. Strain this mixture well to remove sediment from your dyebath. |

| Logwood Liquid | Purple | 0.25-0.5% WOF | 0.75-3% WOF | 3-8% WOF | Liquid logwood is easy to use and will create pale lavender to a dark purple, which will turn nearly black with the addition of iron. |

| Madder | Red | 0.5-2% WOF | 3% WOF | 4-8% WOF | Calcium carbonate at 1% WOF brings out the deep red color of madder and madder used alone will create deep orange-red shades. |

| Marigold Mix | Yellow | 1-2% WOF | 5-6% WOF | 8-10% WOF | This is a super brilliant, cheerful warm yellow. |

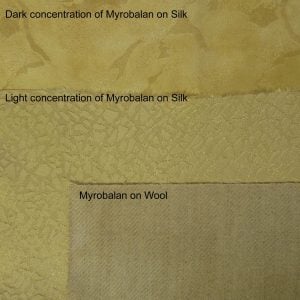

| Myrobalan | Yellow/ tan | 3% WOF | 4-6% WOF | 10-12% WOF | |

| Pomegranate | Yellow | 1-3% WOF | 4-6% WOF | 7-10% WOF | |

| Premium Lac | Red | 1-1.5% WOF | 2-3% WOF | 4-5% WOF | No citric acid necessary as this preparation has been more fully refined, but you may want to strain the dye liquid to remove sediment, which can cause tiny color spots. |

| Quebracho Moreno | Yellow/ tan | 1-2% WOF | 3-6% WOF | 7-15% WOF | |

| Quebracho Rojo | Pink | 1-2% WOF | 3-6% WOF | 7-15% WOF | This color is discontinued |

| Rich Purple Logwood | Purple | 1% WOF | 2% WOF | 4% WOF | |

| Sappanwood Extract | Purple | 1-2% WOF | 5% WOF | 10% WOF | This dye is very sensitive to pH shifts. A pH of 7 gives a very clear purple. Lower pHs can bring out more pink tones and higher pHs can bring out more blues. Please note that the extract dyes differently (more purple) than the sawdust. |

| Tannin | Beige | 1-3% WOF | 4-6% WOF | 7-10% WOF | Very light color used to create dark browns, blacks, and grays when combined with iron or other colored tannin-based dyes, such as cutch. |

| Tara Powder | Beige | 5% WOF | 8% WOF | 10% WOF | Very light “clear” powder that can be used in a similar manner as tannin. |

| Walnut Hull Powder | Brown | 5-10% WOF | 11-50% WOF | 50-100% WOF | This is a powdered raw dye, not an extract, so a larger percentage of dye material is used. At the higher percentages, it is possible to reuse the sediment and create additional lighter colored dye baths with it. |

| Wattle | Tan | 1-3% WOF | 4-6% WOF | 7-10% WOF | A warm pinky beige that also makes a rich bark brown when combined with iron. |

| Weld | Yellow | 0.25-0.75% WOF | 1-2% WOF | 3% WOF | Calcium carbonate at 1% WOF brings out the bright yellow color of weld and soda ash at 0.25% will help dissolve sediment. |

Dissolving Dyes

Make a paste using warm water and wet out the powder. Gradually add boiling water, stirring to dissolve. Some of the dyes like cutch will get quite sticky during this process. You can let these dyes sit for several hours or overnight and they will be easier to dissolve.

Adding Dyes and Fibers to the Dye Pot

Fill the dye pot with water so that the fibers move easily. Add dissolved dyes and stir well. Add mordanted fiber to the cold dye pot and begin heating the water and bring to about 90 degrees F (33 degrees C), rotating the goods gently. Hold at this warm temperature for 30 minutes, then bring the temperature up gradually to 180 degrees F (80 degrees C), rotating gently. Hold at this temperature for 30-45 minutes rotating regularly.

Letting Dyes Cool in the Dye Pot

This is largely a preference for dyers and is based on the observation that some colors will continue to deepen during cool down. However, fibers dyed with Saxon Blue should always be removed promptly once they are cool enough so you can handle them without burning yourself.

Rinsing

Using the same temperature water as your fiber, rinse the dyed goods once or twice to remove excess dye, then wash gently in a neutral liquid soap. Dry away from direct sunlight.

Reusing and Disposing of Dye Baths

Any exhaust baths with dye color left in them may be used to dye additional materials. I keep extra small skeins of mordanted wool yarn and throw those into the exhaust baths. There will usually be some residual color in the dyebath, even after using the exhaust bath and you can further harvest the precious natural dyes by making pigments and lakes from them. Dispose of the used dye baths in accordance with your local municipal guidelines.

thank you so much for the clear instructions! 🙂

I struggle to get even color on cellulose garments. It always comes out a bit streaky despite doing a proper mordant and following the other instructions. Any advice? Thank you!

We’ll add this to an upcoming Feedback Friday!

I’d like to achieve a medium dark green on 100% cotton, can you suggest what I should use/combine? Thank you, Wendy

Hi I would like to paint my yarn with extract and was wondering if you know anyone who has steamed or microwaved the natural extract on wool yarn?

We’ll add this question to this week’s FEEDBACK FRIDAY!

Hi! I dyed some wool with 2% WOF cochineal extract which came out as a beautiful saturated red/pink but I’m having trouble rinsing all of the excess dye out. I’ve rinsed and washed it several times but a lot of dye is still coming out in the water. Any tips?

Hi Erin,

Check out this blog post where we talk about crocking and excess washout!

https://botanicalcolors.com/2018/06/22/hints-and-tips-for-natural-dyers-dealing-with-crocking-fibers/

Best,

Amy

I used a logwood blanket to dye some silks. target pieces Do I need to wash that blanket and re-mordant before I can dye it again in the same logwood dye pot and use o blanket more target pieces?

Hi Sally, Are you asking if you need to re-mordant in order to create another logwood blanket? I’ve read yes, and no. There’s no harm in soaking the blanket in a mordant solution and then back into the Logwood dye pot. In Japan, they call a similar process “middle mordanting” and it increases the vibrancy of the logwood, which in turn may transfer a deeper color to the target. You can keep a bucket of mordant ready as well as your logwood pot.

I thought you do not mordant a carrier/dye blanket because you Want the dye to transfer easily ….

Do I need to use citric acid when using Premium Lac extract? It’s only listed next to regular Lac. Thanks!

Hi Jessica, The regular lac extract has more sediment in it so we use citric acid and filter the dye liquid before adding it to the dye pot. Premium lac does not require citric acid as premium lac extract has much of the sediment removed but we also recommend straining or filtering it to remove any errant undissolved sediment. Thanks so much for the question and enjoy experimenting with the dye!